One such socially significant project for the state is Ekoton+ Company, a leading producer of aerated concrete. The plant construction in 2003 was supported by the Development Bank of Kazakhstan, and in 2004 the plant was already put into operation. Now the company is one of the first enterprises that successfully repaid the loan in 2012 and entered new markets in Kazakhstan. Today, using Ekoton + eco-concrete, about 10.5 mln. sq. m. of housing were built across the country, which is almost five small cities in Kazakhstan. In interview with DBK Talk, Bauyrzhan Baimukhanov, a shareholder of Ekoton+, talked about how the company has developed over all these years and what role the State Development Institute has played in this process.

1. Tell us about the Ekoton+ plant. What is the production capacity today and where are the products output going?

The production capacity of the autoclaved aerated concrete plants of Ekoton+ Group in Kazakhstan is 1,450 cub. m. per day and 550,000 cub. m. per year. This is equivalent to 1 mln. 700 m2 of housing per year. As for the sales market, the plant’s output is shipped throughout the Akmola, Kostanay, Karaganda, Aktobe, Atyrau, Kyzylorda, Mangistau, West Kazakhstan and Turkistan regions. Our products are delivered almost throughout the entire republic, except for the eastern region.

2. Why are the plant’s products so unique? How in-demand is it among the country’s construction companies?

Our aerated concrete fully complies with GOST 21520-89 and has the best characteristics among the wall materials, high strength, fire resistance, moisture resistance, frost resistance, is not subject to degradation, shrinkage and rotting. The plant uses the German production technology of YTONG, the pioneer of industrial production of autoclaved aerated concrete and is a guarantee of German quality, and its products have technical characteristics superior to those of competitors.

The uniqueness of our aerated concrete is its geometry. With this feature the blocks are laid on a special glue, with which you get the minimum seams thickness (1-3 mm). This contributes to lower consumption of masonry material, faster masonry work and less heat loss – with our aerated concrete you do not need to insulate walls, it is warm in winter and cool in summer in a house like this.

Speaking of the demand – in the capital gas concrete takes about 80% of the wall materials used in the low-rise housing construction, over 90% - in individual housing construction. Across the country, about 50% of the masonry material in houses built is a gas block. We cooperate with all major construction companies, including BI Group, SAT Group, Sembol and others.

3. With many years of experience behind, what successes have you achieved? What is the share of Ekoton+ in the construction market in Kazakhstan?

Since Ekoton+ began its work, the following plants have been built and put into operation: AGB plant in Nur-Sultan, AGB plant in Aktobe, lime plant in Alga, restored AGB plant in Kandyagash. With branches in Atyrau and Turkistan, the rest of the regions are covered by long-term partners.

At the moment, the company provides up to 12% of the demand for aerated concrete in Kazakhstan as a whole, and over 20% in Nur-Sultan.

4. In your opinion, what contribution does the plant make to the development of the country’s construction industry? What is the socio-economic effect of the project implementation?

The modern construction industry has a wide range of different materials of building enclosures. First of all, these structures shall meet the following requirements: durability, reliability, fire safety, fire resistance, environmental friendliness and thermal comfort. Today, one of the most popular building materials meeting all of the above requirements is aerated concrete. Its wider application is justified by reduced weight of the product, reduced cost of construction and improved thermal insulation qualities. These and other factors, with a relatively low price of aerated concrete, increase the relevance of autoclaved aerated concrete for quality housing solutions in the country.

Definitely Ekoton+ sets the quality standard for aerated concrete and for wall materials in general. The product of our plant is a reference - the perfect geometry, the optimum density of D500 and a strength of 2.5, sufficient for the construction of self-supporting house up to 3 floors. Other plants look up to us, but Chinese equipment does not allow them to achieve such quality characteristics.

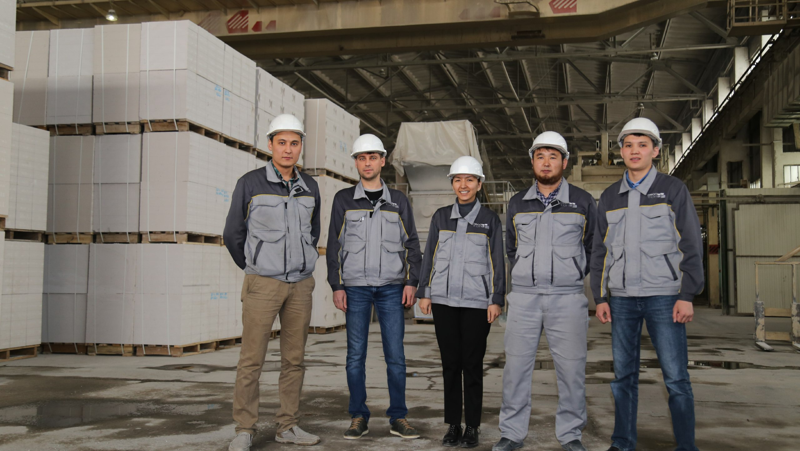

Moreover, the Ekoton+ Group enterprises employ over 700 employees, who are provided with a full social package. Since there is no analogue of the equipment in the Republic of Kazakhstan – new employees are certified and trained when hired. It should be noted that the company has created a mentoring program for this purpose.

5. Tell us about the role of the Development Bank of Kazakhstan in the history of the company, which became a leader in the production of building materials?

Undoubtedly, Ekoton+ remembers its first partner, who believed in the economic and social importance of the project and supported us at the start. We were among the first DBK customers from 2003 to 2012. Then, thanks to loan from the Development Bank, in one year we built from scratch the largest plant in Kazakhstan, which since 2004 has been working in three shifts 24/7 for the prosperity of our country and building great cities. The total project cost was USD 12.76 mln. with DBK contributing USD 6.04 mln. Looking back, we note that the Bank supported us in the crisis years as well. For example, in 2009, in order to reduce the debt load, the Bank restructured the loan of Ekoton+.

The success of the company and constructive cooperation in those years is also confirmed by the opening in 2008 of a new enterprise in the west of the country – in the city of Aktobe, which covered the market of the entire region.

6. Tell us about further plans for the company’s development.

The company plans to enter new foreign markets. A project in neighboring Uzbekistan, in the city of Angren, is nearing completion. The planned capacity of the plant is 300 thous. cub. m., the lion’s share of which will cover both the markets of the neighboring country, and the southern regions of the country.